A line following robot. by James Vroman

![]()

Design Goal:

The TechBot1 is a small line following robot designed for for the

1998 Embedded Systems conference in San Jose California. It was

built by Jerry Merrill and myself and was designed as a promotional

robot that would follow a black line drawn on a dry erase board.

![]()

Motive Power:

The TechBot1 uses 2 Cirrus CS-70 servos that have been modified

for full rotation and have had their controller boards removed to

convert them from servos to gear motors.

Servos are a common motive power for small robots due to their

low cost, ready availability, standardized sizes and the fact that it

only requires 1 bit on your processor to control the motor.

We initially tried this approach but found that the speed control was

very minimal with a finer control needed for this application. The

servo controller boards were then removed and the wires soldered

to the motor terminals and case ground. The motors were then

controlled by an H-bridge circuit to allow direction and speed control

with only 2 processor bits per motor. Initially a 4 transistor Bridge was

used but during power up the transistors would turn partially on and

start conducting. This was corrected by adding a 5th transistor to the

top of the H-bridge to control motor power. This also simplified the

software into having one bit for direction and another bit for

power/speed control per motor.

![]()

Sensors:

In order to follow the line I/R reflective sensors were used to

detect if a line was present or not. The sensors chosen are the

QRB1114 from QT Optoelectronics and have a focal point of

about 1/4 inch. They are available from DIGI-KEY.

Most line followers use 2 or 3 sensors of this type to do their

detection. This works but does not give the ability to follow

lines with very tight turns. We used an array of seven sensors

arranged in an "inverted V " arrangement placed

under the front of the robot behind the skid wheel. The sensors

are wired with all the receivers connected in parallel and fed to

an LM311 comparator to set the threshold trigger level with it's

output fed to a processor bit. Each transmitter LED is connected

through a current limiting resistor to a processor bit. This allows

the entire array to use 8 bits for the sensors.

![]()

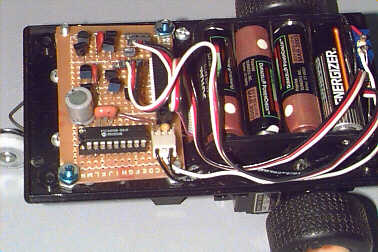

Processor:

The PIC16F84 was chosen for it's small size, easy reprogramability

and interrupts ( the fact that we manufacture a PIC processor

emulator also helped in this decision). It is clocked at 4 MHZ by

a ceramic resonator and is powered by 4 AA rechargeable batteries.

These same batteries power the motors. This is usually not recommended

since surges in motor current can affect the processors operation, but with

decoupling caps in place and the watchdog timer being used in the

software no problems were experienced. The watchdog could reset the

processor if it went stupid before you could ever see it act up.

![]()

Mechanical:

The servos were modified for full rotation by disassembling the servo

to gain access to the gear compartment. The main gear is then removed

and the stop that keeps it from rotating removed with an hobby knife.

The plastic key that keeps the feedback pot hooked to the main gear is

removed to allow full rotation without moving the feedback pot. Once

it was determined that the servo controller board did not provide

enough control, it was removed and the feed back pot removed as well.

The wires were removed from the control board and resoldered to the

motor terminals. The servos were reassembled and taped together.

This assembly was then attached to the bottom of a plastic case with

double sided tape. For this application the circuitry was split into a

sensor board and a processor/h-bridge board. The two boards were

connected by a ribbon cable. The entire assembly could be built on

one circuit board with the same board being used as the chassis.

The sensor board is mounted under the front of the chassis with

the processor/motor control board above. A skid wheel (closet

roller wheel with a music wire frame) is attached to the front

of the robot.

The battery holder is mounted over the motors to keep the weight

to the back and over the drive wheels.

The drive wheels were salvaged from a toy car and bolted to the

servo horns with #2 bolts. Hot glue will work for a while but

eventually will come loose. Both the Dallas Personal Robotics Group

and the Seattle Robotics Society have more information on

modifying servos for use in robotic applications.

![]()

Firmware:

The program is divided into 3 sections - The main program loop,

The pwm isr ( pulse width modulation interrupt sub routine) and

The action routines. The program functions to turn on the

transmitter portion of the sensors in order of priority and see

if a line is seen by the receiver section. The outer sensors are

tested first. If a line is seen then one motor is reversed while

the other continues forward. If no line is seen the next set in

are checked. If a line is seen here then one motor is stopped

while the other continues forward. If no line is seen here then

the next set in is checked. If a line is seen here then the speed

of one motor is reduced while the others speed is maintained.

If no line is seen by these sensors then the centermost sensor

is checked. If a line is seen here then the motors are set for

both full forward (we reduced this from full speed for better

reliability). If no line is seen by this last sensor than the last

motor setting is maintained in hopes of finding the line again.

Once a sensor detects a line and sets the motor settings then

the sensor routine is started again. In this manor priority is

given to the outermost sensors for the biggest corrections

with the more minor corrections being serviced last. More

details on this can be seen in the code listing. The firmware

was developed using the ClearView Mathias PIC emulator

and assembler which can be downloaded for evaluation

from HTTP://www.tech-tools.com

![]()

Real world:

The robots worked well with a run time of over 6 hours

per battery set. Three robots were built for the show and

all were still running at the end of it. The reliability and

the crowd that they attracted was better than we had

hoped for.

![]()

What's next?

The firmware could be updated to give more decision

capability and a memory of the corrections. If the robot

gets off course and intersects a line with both outside

sensors it can sit there and oscillate till a sensor clears

the line ( this caused many laughs at the show). A search

capability that if the line is not seen in a certain period

of time it can run a search pattern to locate the line

would be a good addition. With only one I/O line left

unused the hardware expansion is limited but I/O lines

can be recovered by using a 74HCT138 to use three lines

instead of seven for driving the sensor LEDs. I have

implemented this in my JavaBot1 with no degredation

in operation.

Add a speaker or sound effects chip. Robots

that make noise get far more attention than ones that do

not. The recovered I/O lines could be used for more sensors

or as a buss to talk to other processors.

Only your imagination will limit you.

![]()

Jerry Merrill is the founder and CEO of TechTools, a company

that specializes in memory and "PICmicro" emulation products

and development systems.Jerry has been involved in electronics

for over 23 years.

![]()

James Vroman is a Technical sales and support representative

for TechTools and an active member of the Dallas Personal

Robotics Group. James has been involved in Electronics for

over 15 years and can be reached at james@vroman.com.

![]()

Sources:

DigiKey-HTTP://www.digikey.com

TechTools - HTTP://www.tech-tools.com

Dallas Personal Robotics Group - HTTP://www.dprg.org

Seattle Robotics Society - HTTP://www.seattlerobotics.org

James Vroman -HTTP://www.james.vroman.com